OPC

Router

The Communication Middleware. Innovative. Simple. Effective.

With the help of the central Industry 4.0 platform, data exchange in your networked production processes is automated and optimised. The OPC Router connects systems vertically and horizontally, from sensor and controller to ERP and cloud, from printer and scale to MES, SCADA or LIMS. Find the solution for your connectivity project from the multitude of Plug-ins and request your personal download.

Middleware for industry

Automate your data exchange

The successful implementation of Industry 4.0 requires smooth networking of machines and seamless data acquisition directly at the source. Here, the use of edge devices and the collection of machine data via interfaces play a central role, as they enable the automation and optimization of processes. In order to effectively use the collected data, reliable IT/OT connectivity with middleware technology is of great importance. In addition, the connection to the cloud opens up numerous advantages, such as the ability to retrieve data from anywhere and at any time.

These and other customers rely on the OPC Router

Make your production transparent

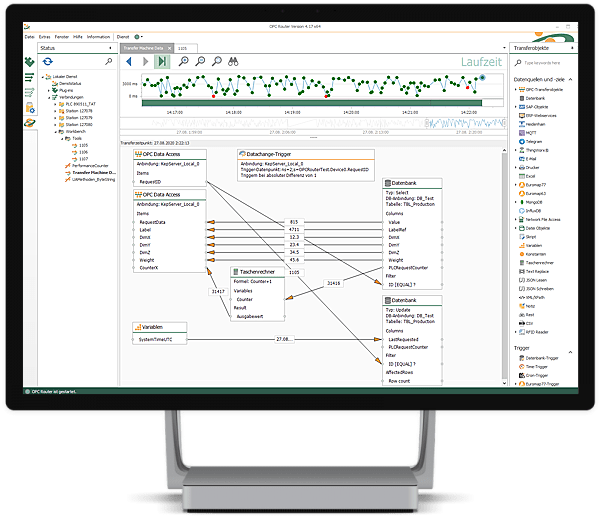

The OPC Router is the central communication platform for your projects in industry. It is based on standard interfaces for automated data exchange across all levels. An important communication protocol for Industry 4.0 is OPC. As OPC client software, the OPC Router directly supports the establishment of Internet of Things (IoT) & Industry 4.0 communication.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationDigitise your production

The OPC Router enables you to optimise and digitalise your production processes. The automated data exchange takes place through the integration of systems such as OPC UA, SAP, SQL, MQTT, REST, SOAP, Excel, labellers etc.. The recording of process data enables you to have a continuous overview of your production.

Graphic configuration, exemplary monitoring and extreme reliability make the OPC Router a pioneer for your Industry 4.0 projects.

This is what our customers say

Processes via OPC Router run absolutely resilient and stable. The step-by-step automation of our production with the OPC Router has proven itself.

Hardy Schwenke, HERMA GmbH

In projects like these, we created an integrated system for industry 4.0 with inray, which we can flexibly adapt and supplement as required.

Michael Kalbe, Auria Solutions GmbH

The OPC Router was easy to implement and enables our systems to communicate smoothly in line with Industry 4.0.

Alexander Vierlinker, iwis – Joh. Winklhofer Beteiligungs GmbH & Co. KG

The OPC Router is the heart between the database and the ERP system. It convinces with the very simple connection of business data and production data, which means that the software more than meets our requirements.

Ralph Sagberger, corratec

In the past, orders for the production lines were entered in the SAP® system and manually transferred to an Excel list. This Excel sheet was printed out and had to be distributed to the various production lines. This was already very cumbersome for the production!

Michael Lindel, Manfred Oswald, DMK GmbH

We made the experience that we can integrate our systems with OPC Router into almost every production line without any problems. We profit from the fact that many industrial companies already rely on the OPC Standard – this simplifies networking and saves our customers time and costs.

Andreas Waneck, X-Rite Inc.

OPC Communication was still in its infancy at the time, but OPC Router was already working reliably and was easier to configure and operate than other solutions. The service provided by inray was also a good match.

Thomas Ruppmann, Andreas Stihl AG & Co KG

OPC Router has enabled KennaMetal to not just stream machine data up into the cloud seamlessly, it also allows us to pull and combine information from SAP and other data sources to have a more uniform data set for machine learning and dashboarding.

Paul Baker, KennaMetal

Test now –

Get your free

OPC Router Demo

Request your free download link now for the latest version and look forward to:

- Fully functional demo version

- No-code data transfers

- All connectivity options

incl. OPC UA, REST, MQTT, SQL, SAP - Tutorials and technical support

In addition, we inform you about interesting facts and industry-relevant information on the topic of industrial digitalization and Industry 4.0.