Heidenhain

Heidenhain CNC control connection

Heidenhain CNC controllers are one of the leading CNC controllers in the market. By using the same communication protocol, controls of different series and years of manufacture can be connected in the same way. A Heidenhain CNC machine can be easily connected using OPC Router Heidenhain Plug-in.

The communication protocol is used to retrieve the data points of CNC machines hierarchically and select them for setting up data transfer connections. The data points of the control can be read and written.

The compatible Heidenhain controllers:

- iTNC 530

- TNC 128

- TNC 320

- TNC 620

- TNC 640

- MANUALplus 620

- CNC PILOT 620/640

- MillPlusIT V6x0

- GrindPlus IT/640

That’s how easy it is.

Heidenhain connection via drag & drop

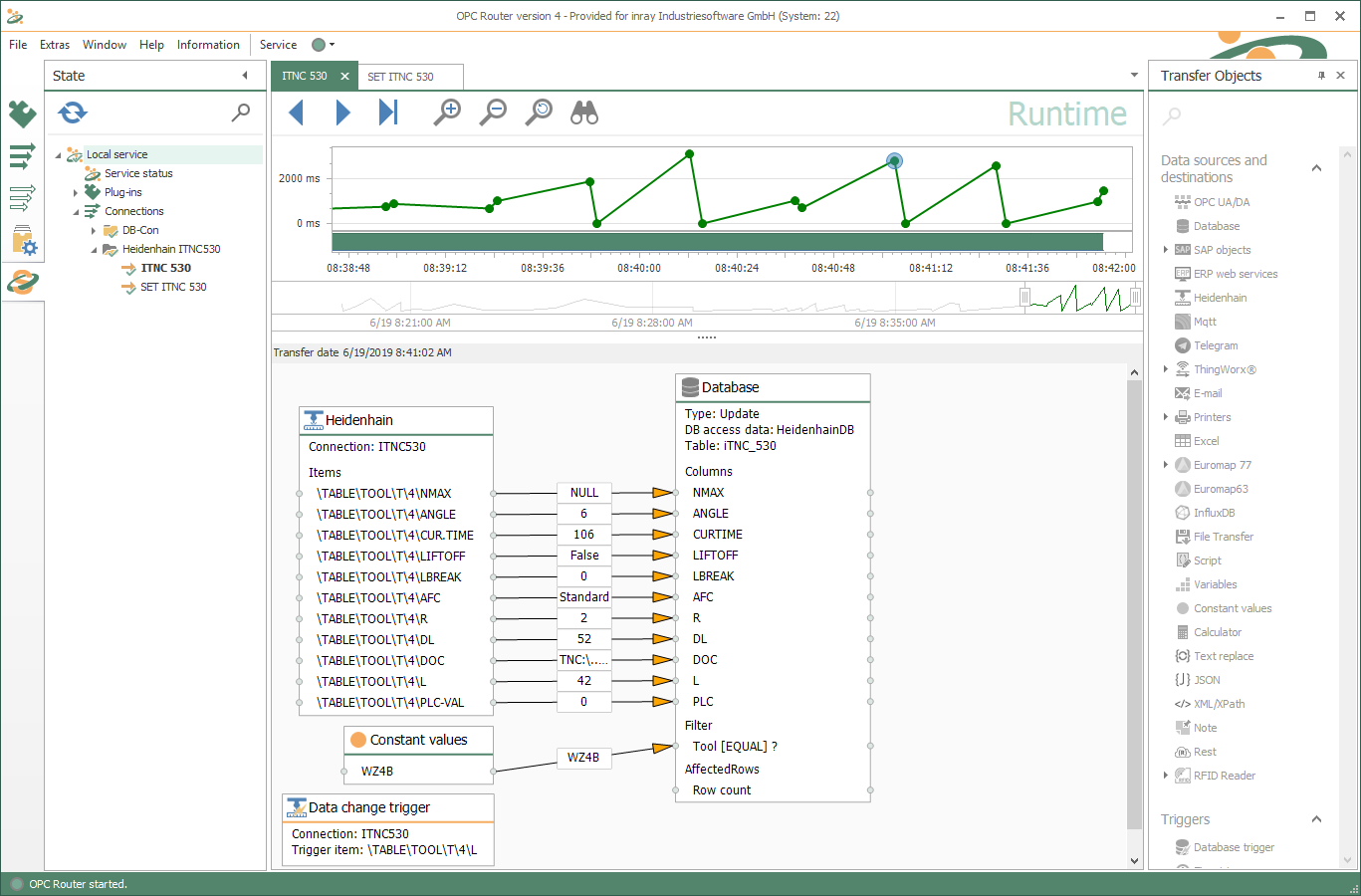

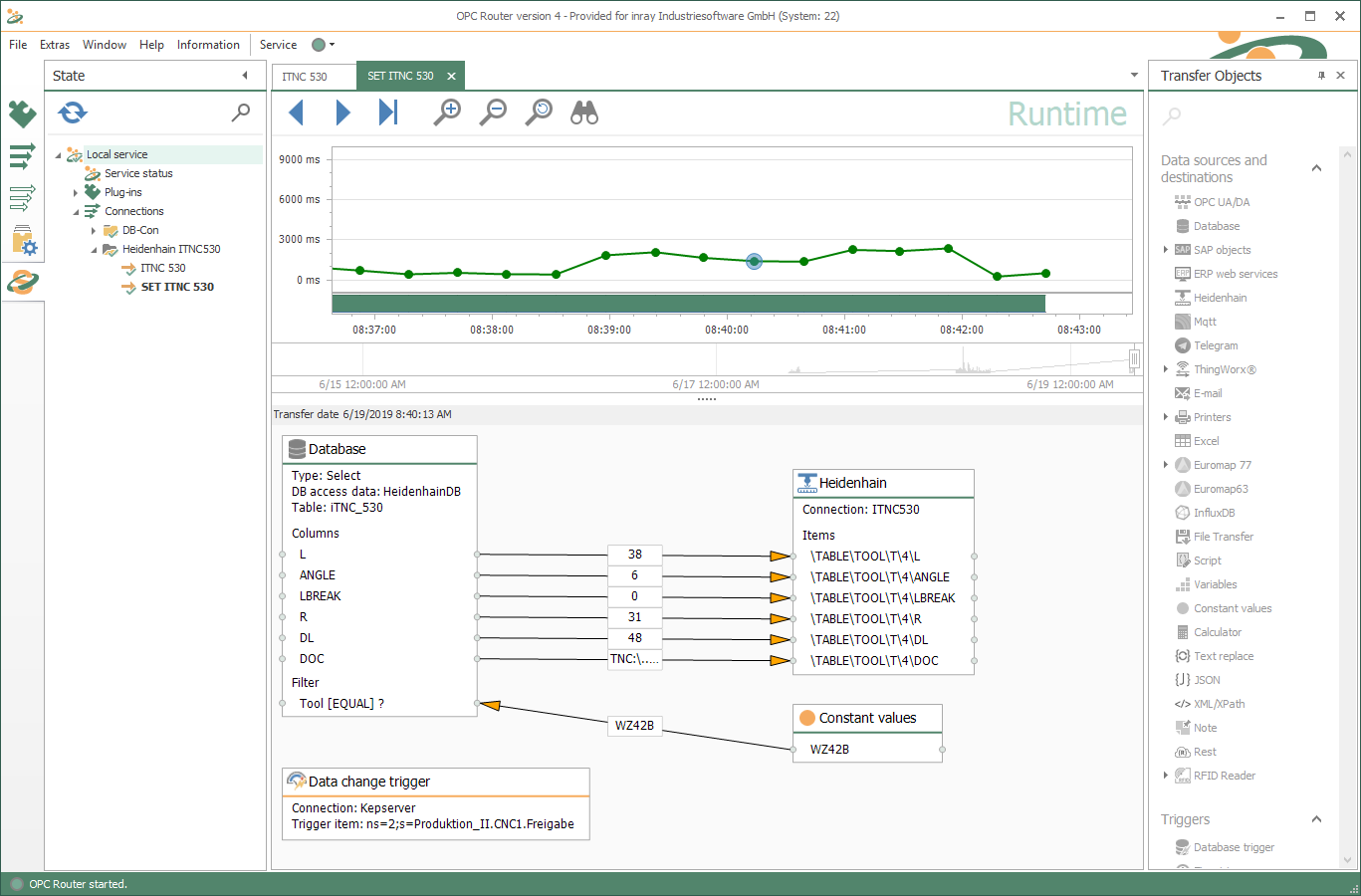

Connecting your systems to a Heidenhain CNC machine is very easy and intuitive with the OPC Router via drag & drop. These screenshots show you an example of an application of the OPC Router and a Heidenhain CNC machine. The first screenshot shows how the Heidenhain CNC machine sends data to a database for data recording. The second screenshot shows how, for example, order data for control is sent from a database to the Heidenhain CNC machine.

Bringing Industry 4.0 to life with Heidenhain

- Achieving more with coupled systems:

The CNC machine is the birth place of the product. It is therefore more important that machines are integrated into the production IT system. The exchange of parameter specifications as well as the feedback of process values brings great potential for optimization. - Industry 4.0 and Heidenhain:

Industry 4.0 is the new way of producing. Basic idea is the best possible networking and interaction of all involved systems in the production. The Haidenhein Plug-in integrates the CNC machine into the Industry 4.0 infrastructure. - About OPC Router:

With the OPC Router you can realize the networking of your systems in a graphical way. With its Plug-ins, it becomes a data hub in industrial environments and enables the integration of your CNC machines into IoT and Industry 4.0. Simple configuration, sophisticated monitoring and robustness characterize it.

Heidenhain Plug-in application examples

Process data acquisition

The first step towards optimizing production is to create transparency. This is the only way to uncover and verify potentials. In addition, after implementing measures, transparency makes it possible to check successes. Transparency is achieved by process data acquisition. Important process data are recorded and provide information about condition of the machine and progress of important process values. With Heidenhain Plug-in of OPC Router it is possible to access all data points of the CNC machine and transfer them to any target system. If data is written to an MS SQL database with the SQL Server Plug-in, for example, evaluations can be carried out directly in the database and visualized via corresponding clients. Data can also be transferred to IoT platforms via MQTT for evaluation in the cloud or via BigData.

Parameter setting for CNC machines

Manual input of production parameters is time-consuming, error-prone and creates costs. According to the approach of Industry 4.0, exactly such processes should be eliminated with help of networking and communication between all systems. With OPC Router and Heidenhain Plug-in it is possible to load production parameters from any source system and transfer them to the CNC machines automatically at the beginning of production. Depending on the structure, ERP systems (SAP, Navision via WebServices, etc.), databases or PLC controls serve as sources.

Connecting Systems

Transfer-Objects

The transfer object of Heidenhain Plug-in allows access to data points of the Heidenhain CNC control.

Data points

The Heidenhain control defines structure and organization of data points. Each data point has a unique name. As client you get the current value from CNC control. The desired data points are selected via browsing. Data points are available in the transfer object of the graphical configuration and can be connected with other fields during transfer.

Trigger

The Heidenhain Plug-in provides different triggers.

DataChange-Trigger

The datachange trigger is configured for a CNC datapoint and triggers the transfer when the datapoint is changed.

Limit value trigger

The Limit value Trigger monitors a data point for compliance of limits. It can be checked for exceeding or falling short. A hysteresis can also be configured.

Bit-Trigger

For data transfers, handshakes are often used. The bit trigger is here the simplest way. OPC Router checks whether a bit requests a transfer. Once transferred, the bit is optionally reset or another bit is set as response. The success of the transfer can be transmitted to another data point.

Message-Trigger

The message trigger is the further development of the bit trigger in form of exchange like in a telegram. Not only a bit, moreover a counter is checked for a value change. In response, the number that triggered the transfer is written back after transfer. Reliability and traceability of this exchange is significantly higher.

Browsing

The Heidenhain Plug-in can browse data points of the CNC control.

Data point hierarchy

The CNC control supplies data points in a hierarchical structure in form of a data point tree. OPC Router reads all data points as a tree and displays them to the user. In this form, even large datapoint quantities are easily accessible. Each data point is identified via the unique path and is taken over including type information.