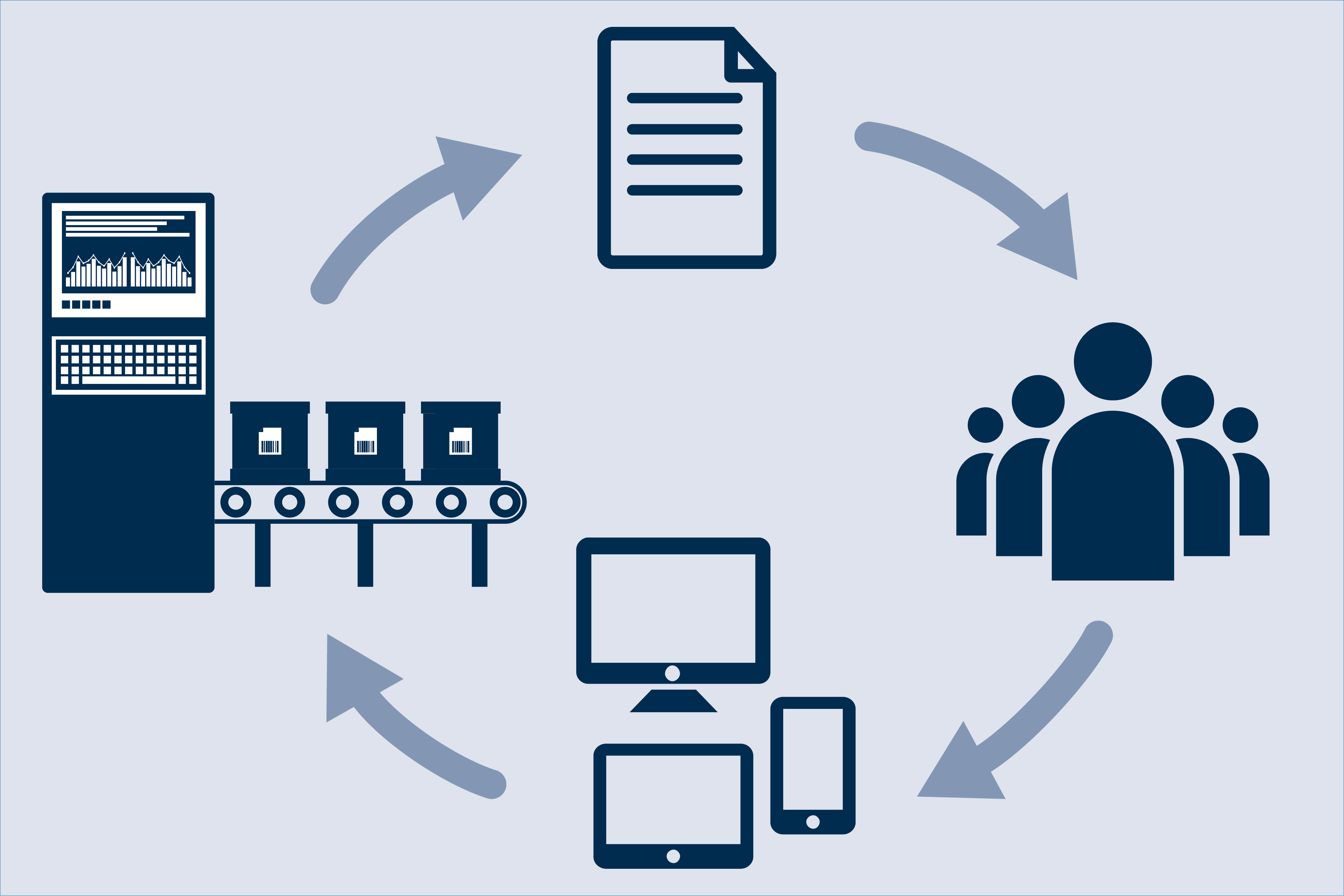

Networked production management prevents data redundancy and digital divides

Removing media gaps: That’s at the core of Industry 4.0 (What is Industry 4.0?). The aim is to close all media gaps in manufacturing industries. As they are precisely the reason why present-day manufacturing potential cannot be utilized fully. Five areas in production are particularly affected: They slow down production processes, and increase both error rates and workload.

If these five digital communication gaps as they occur in production are eliminated by closing the media gaps, the advantages of interconnected information technology (IT) and of digitally cross-linked operative technologies (OT) can be utilized in the best possible way. Networked production need not be difficult, if production entities makes use of one common communication standard, which joins all systems, machines and devices seamlessly together for cross-platform communication.

1. Critical Media Gap: Manual Record-keeping of Process Values

If an production environment isn’t fully digitally integrated, this essentially implies that production lines and spaces aren’t seamlessly interconnected with a company’s entire architecture of manifold systems. The downside: Process values and other results (i.e. actual machine data), as available in the respective machines, are not readily accessible across all production levels. In production buildings, a variety of machines are operated that are oftentimes made use of as insular solutions. Although the machines operate well throughout the production process, in accordance with their respective technical characteristics, the machine’s record-related data activity cannot be accessed via an interface to be made available in a seamless dataflow. Important process values and results must be manually read out (i.e. written down by hand), and then manually typed into another system. An machine operator has to literally transfer the data off the machine display into a list by jotting everything down a sheet of paper, to produce that needed record of the machine’s data activities. This way of working is a sad reality in many production environments and causes error-prone operating processes. Workflows aren’t smooth but rugged. Writing errors during transcription occur regularly. In total, one is up against slowed and error-prone workflows.

The situation is different when the media gap is eliminated directly at the machine: Machine and production data can be relied upon. Production-related process values and results reliably reach their desired destinations in their respective target systems because networked data transfer warrants error-free transmissions; as long as connectivity schemes are carried out by-the-book, to prevent data redundancy. Centralized access to solid information empowers both staff members and managers to continually keep pace with production units. Important process values and other needed data can be attained in a timely manner, which allows interference with production processes just in time, when inference is needed. Networked dataflow ensures information transfer about error messages and fault reports – for instance about energy consumption and production times – are transmitted just as much as production history reports for any given product.

Through Industry 4.0 interoperability process values and results can be networked and managed centrally – via Open Platform Communications via OPC UA Protocol. Thus providing the means to transfer your entire production data quickly, reliably and fault-free – for connectability to PLCs and other systems. Once this is set up, you have rid yourself successfully of manually maintained process value lists. The data almost gets underway practically by itself, reaching its target destination safely – with the OPC Router provided by inray.

Get connected now: Cross-link your machines in your production with the OPC UA plug-in for reliable interoperability between your machines and other systems with full access to automation components.

2. Critical Media Gap: Important Production Data is left without Database Connection

If machine data is processed in Excel lists, Excel is used as stopgap “database”, and thus as makeshift solution for this media gap in production. Excel can be used as versatile and useful but isolated tool for documenting machine data. However, it can never produce the diversity of applications and quality of performance a good database has to offer. The downside: Production data sitting in excel sheets are not industry 4.0-compatible, which means these excel sheets are not readily accessible within an otherwise Industry 4.0-ready environment. These excel files can be used as powerful digital information carriers; however in separation to the production environment. This is precisely why excel lists are only partially helpful for processing information, as they do not measure up against state-of-the-art information management and are not very well suited for dissemination of information. Carrying out data maintenance tasks is hard to do in a reliable way in Excel, too. Mainly because it wasn’t designed to be used as database in the first place and does not offer Industry 4.0-compatibility in and of itself. It is also not possible to connect Excel to IoT systems without suitable middleware. Even though it is possible to make use of Excel in multiple ways, it falls way short compared to dynamic data management. To copy the data from various machines, to then carry the information over by filling out lists and to then enter the data from the lists into excel sheets in order to be able to work with the data, doesn’t only double the workload but multiplies it.

The situation is different, when the media gap is closed by tackling necessary data maintenance and retrieval tasks – by reading out the data that is available in the machine directly at the machine and sending it to a designated database. Machine data can be sent to a database directly, if the appropriate data protocol is used for data transfers and if a powerful middleware ensures that transactions can be carried out on a 24/7 basis. Databases like MySQL, Oracle and ODBC offer manifold possibilities for data storage. If all machines in production are connected with powerful databases, the data can be fully exploited because all the available data becomes accessible and can thus can be utilized to its full potential. If a company cannot do without Excel lists for dealing with administrative subtasks, the needed data can now be read out from the database, which eliminates manual copying work at the machine: Handwritten lists now don’t have to be transferred into Excel and don’t have to be kept up-to-date by human effort.

Through Industry 4.0 interoperability machine and production data can be managed fast and profoundly. Your machine data becomes quickly available in your database – with the OPC Router provided by inray.

Get connected now: Send your production data directly to your database; for instance to MySQL, ODBC, Oracle or SQLite. You are now ready and set for OPC UA Data Access Automation – with the graphical user interface of the OPC Router, which makes work routines on data connection fast, easily overseeable and transparent.

3. Critical Media Gap: Getting Paper Data into ERP by Entering Data Manually

If handwritten notes become main information carriers, chaos soon follows. It make little sense to enter data manually into an ERP system. It is a trivial pursuit. The downside: You are transferring data by time-consuming human effort. Instead data could be easily sent to your ERP system via appropriate middleware. Handwritten notes can easily get lost between production and administration. The data contained in paper documents might not be correct. Lists might not be properly filled out and could contain gross misinformation that would then live on in your ERP system as dirty data. Entering wrong dates or values or mixing up order information results in dirty data, which wreaks havoc in any organization or enterprise. The media gap between manufacturing and administration, where the managers of various business units and production lines have their offices, is particularly sensitive. This is due to the fact that staff members who are not working directly in a company’s production hall cannot monitor work processes in production and cannot examine them throughout running procedures either. They always have to pick up the phone or write emails or walk over to the production halls in order to keep informed about what’s actually happening in production. It is likely that decision making processes are slowed down because of it or that problems in production are either noticed or reported much too late to production line managers. If this media gap isn’t closed, actually determining optimization possibilities early on and implementing them in a timely manner won’t be possible either. Sometimes optimization opportunities remain completely unidentified.

The situation is different when the media gap is closed by getting rid of the paper chase. Machine and manufacturing data as well as diverse alerts or notices, which are important for maintaining productivity as well as for quality assurance, find their way into the ERP system, without detours. In many cases a company’s data network is comprised of many subnets that should be able to communicate with each other to offer seamless Industry 4.0-capabilities. When SAP acts as main management platform, which is connected with all your company’s subnets, this results in well-arranged data management and rids you of “paper data” once and for all – if a middleware is put in place that closes the media gap.

The ideal scenario: Information is fed into the ERP system from all data sources available in the enterprise and can be retrieved from everywhere, too. If your company is put in that fortunate position, you have reached your goal to implement end-to-end data management (E2E) in your company. Now all data that is produced in your company can be made use of in a holistic and agile manner. The OPC Router ensures that this works out in practice: Data are accessible just-in-time, and can be verified and validated in an enterprise-wide network during running procedures. Moreover, approval processes can be defined to reduce risks to an absolute minimum. Database data delivery makes use of preprocessed data. Data storage in databases is possible for orders and recipes.

Through Industry 4.0 interoperability enterprise-wide accessibility of all machine and production data is possible. Data is fed into your designated ERP system – directly and without delays.

Get connected now: Don’t get hung up with handwritten scribbles and notes. Win your paper chase by sending your data directly to your SAP ERP system. Make use of the plug-in for SAP Systems, made available for the OPC Router by inray.

4. Critical Media Gap: Entering ERP Data Manually into Labeling System

When labelers or labeling systems are not able to retrieve any or all needed information from the ERP system, labeling becomes a risky business. This risk occurs at an important intersection of the company. The downside: Data might well be full of errors. It takes additional effort to verify the correctness of the data, as one can never be quite certain if the data is totally faultless and thus can be relied upon fully. Unfortunately, data are often stored in several different systems. The problem with this is that if these respective systems are not interconnected via an enterprise-wide information platform – or cannot be stored as specified data telegrams – they cannot be checked for errors holistically (i.e. checking all data together in one place). More time is needed to verify the correctness of data involving various departments, as the needed data is derived from data sources from customer service, order handling, production and dispatch. Only when all needed data is put together the printing of labels or the printing directly on packaging material vial respective labelers or printing systems can occur. In the worst case scenario printing labeling goods or packages ready for dispatch with incorrect data will cause overall higher overhead costs and will also result in expensive rejects.

The situation is different when the media gap is closed by directly connecting labeling systems to the designated SAP ERP system. Required data packages become instantly available at the labeler or labeling systems. Provided that a productive middleware establishes the required connection, data packages can be sent as data telegrams to the printer, labeler or printing unit. In practical terms, this means that the required production data package is sent to already defined data fields at the addressed printer; and directly into the respective stored layout for correct printing of predefined printing formats. Important data needed for printing labels – or packaging as well as packages for dispatch and their accompanying dispatch documents are e.g. item and lot numbers and quantities. As is customary, MHD and batch numbers as well as SSCC barcodes are often printed. The Serial Shipping Container Code (SSCC) is an 18-digit number, mostly also represented as barcode, used to identify logistics units, which helps identify shipment items correctly and to also track them all the way through from respective dispatch locations to target destinations. A lot of information is needed to label products in compliance with rules and regulations and to ensure that goods are surely sent to the right recipient.

Through Industry 4.0 interoperability labelers and printers can be integrated into an existing Industry 4.0 infrastructure. When this connection is made, your SAP data are sent in the right data format to the printer and then printed on the correct label in the correct format – via the OPC Router, made by inray.

Get connected now: Establish that direct link to your printing system. Smarten up your labeling and printing stations. OPC Router plug-ins are available for Zebra printers, Domino labelers, Wolke printers, MS Windows printers, as well as for Generic Printers (TCP/IP).

5. Critical Media Gap: Manual PLC Parameterization with Data printed out from ERP system

In an automated production environment nothing is worse than a media gap that requires PCR parameterization by hand (e.g. for recipes and order information) – right at the heart of highly automated production plants. This need not be, by all means! Do you really want to adjust parameter settings manually? Do you really want to use your ERP system apart from your production environment? The downside: Work processes are slow and drag along because parameterization takes time, if human interaction is required for every single change notice that makes parameter changes necessary. It’s futile to go about your production business in this way, as machines developed around the turn of the millennium are equipped with CNC or PLC technology and are waiting to be interconnected with an intelligent communication network; for instance when you establish a connection to the Siemens S7 protocol.

The situation is different when the media gap is closed by establishing a direct connection to ERP/MES and PLCs. The ERP system sends parameters and other adjustment data directly to the machine’s PLCs. An easy-to-use connection tool with graphical user interface, as provided by the OPC Router, puts all connections into perspective at one glance, thus allowing good oversight and comfortable management of all PLCs. Automated PLC parameterization becomes possible – with no transfer limits at all. The machine can be parameterized all-automatic, which limits operator interaction to an absolute minimum and can eliminate user interaction fully in some cases. Moreover, other important changes can be prompted via ERP/MES, impacting the machine in the production hall directly. The level of impact one has can be limited to regular data transfers only but can also be extended to include data packages for approvals or clearances and refitting orders. This will depend on each company’s preferences and and possibilities – and especially upon an enterprise’s specific Industry 4.0 network environment and how interconnections between systems and machines are set up in detail.

Through Industry 4.0 interoperability automated control systems solutions become reality by interconnecting ERP with PLCs. Once established, data packages with parameters become available for PLC parameterization where they are needed. Put your machine control on the fast track – with the OPC, provided by inray.

Get connected now: Get the most out of your PLCs. Take control of your PLCs from the top: Directly from inside your ERP system. Build that bridge between ERP and PLCs – for direct data transfer by using the OPC Router plugin for SAP systems.

Additional related information:

Information about our diverse scope of plug-ins can be found here: OPC Router – Plug-ins

Run a free test now!

Get your personal link to the most recent OPC Router configuration and sign awake for product news.