Microsoft Excel

Microsoft Excel

The spreadsheet program Excel is the most widely used tool of its kind. A lot of information is administered, stored and calculated manually in tabular form. The OPC Router can access the files with the Excel Plug-in, with access to all tables and cells to read and write data. You can find a dedicated video about this topic by visiting our tutorial stream

That’s how easy it is.

Microsoft Excel connection via drag & drop

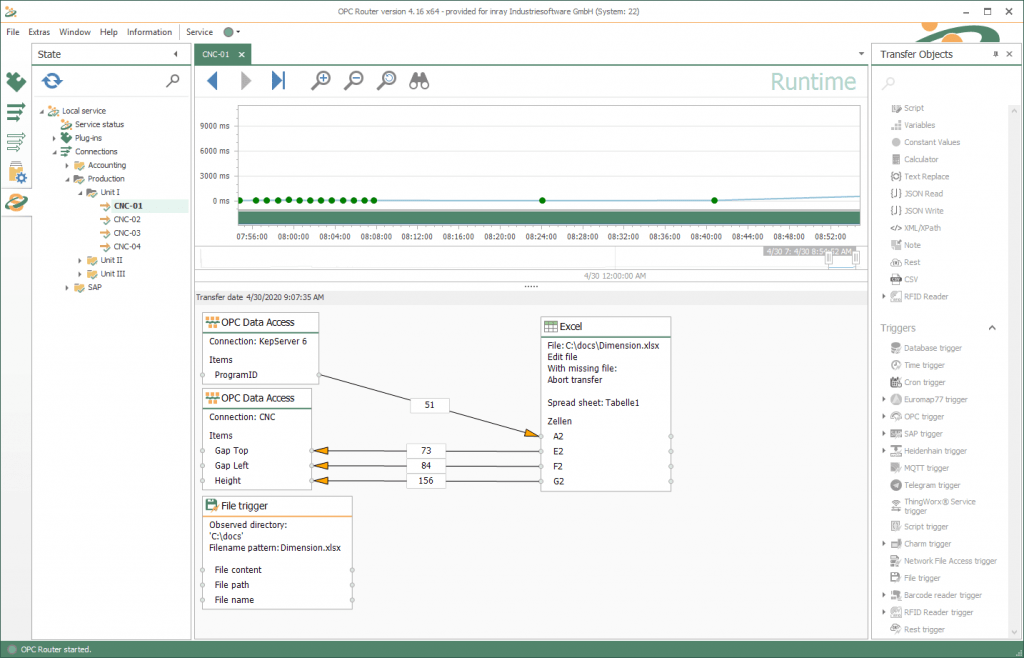

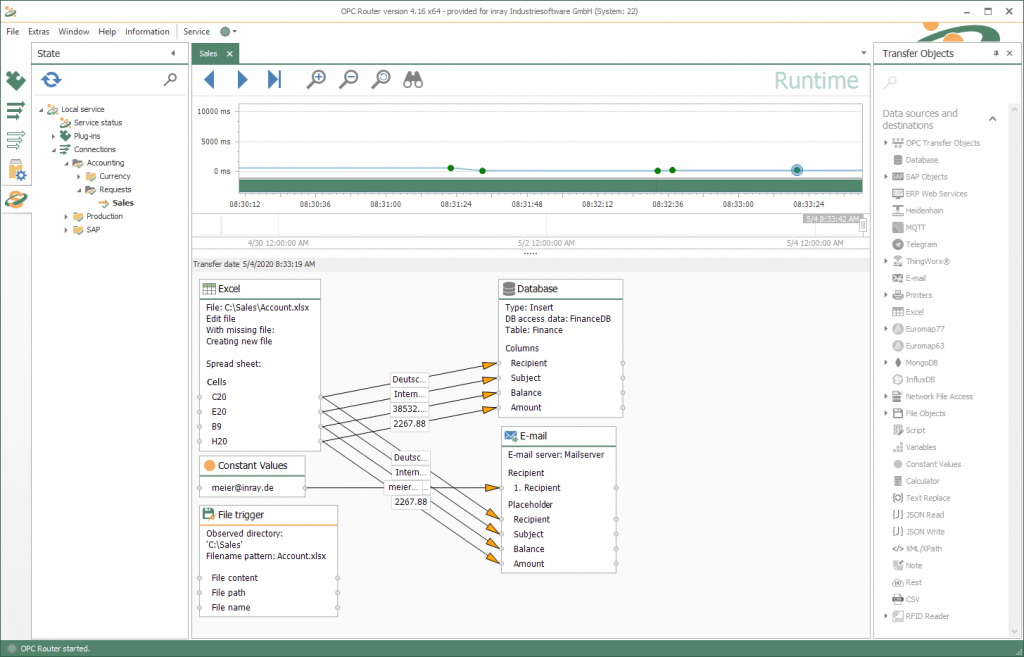

Connecting your systems to Microsoft Excel is very easy and intuitive with the OPC Router via drag & drop. The screenshots show you an example of an application of the OPC Router and Microsoft Excel. In the first screenshot, OPC UA data is written to an Excel document via the OPC Router. Then, in the second screenshot, this data is saved from the Excel document in a database and simultaneously sent by email to other departments, for example.

Bringing Industry 4.0 to life with Microsoft Excel

- Achieving more with coupled systems:

Instead of manually transferring data from other systems to Excel, this process can be automated with the OPC Router and the Excel Plug-in. Machine data acquisition is set up easily. That saves time and increases data quality. If data is read from Excel and transferred to subsystems, Excel even serves as a source for recipe- or machine-parameters. - Industry 4.0 for Excel:

Excel users implement complex process knowledge in data tables and perform manifold calculations with the contained data. Integrating Excel to make it a part of an interlinked production systems network utilizes and multiplies knowledge and information – to make it both useful to and usable for the whole business enterprise. - About OPC Router:

The OPC Router offers a visual network configuration interface for successful cross-linking of your systems. A high variety of Plug-ins turns the OPC Router into a powerful data hub for industrial applications.Easy configuration, sophisticated monitoring and robustness are main distinguishing features of the OPC Router.

Microsoft Excel Plug-in application examples

Recipe specification for prototype systems directly from Excel

In practice, Microsoft Excel is often the first choice for prototyping. In plant engineering, Excel can be used to quickly set up calculations and determine machine parameters. This applies to development as well as to commissioning in production. To quickly link the values determined by prototyping with the real plant, values from cells of the Excel calculation can be written directly to OPC UA data points using the Excel plug-in via OPC UA Client Plug-in. If the parameter set is recalculated, the OPC Router retransmits the data per trigger to the plant PLC before the next test run. Once the optimum parameters have been determined, they can be permanently transferred to the plant’s recipe controller.

PDA via OPC directly in Excel

In practice, PDA-systems offer valuable and well thought-out evaluation of recorded machine data. In special cases, such as troubleshooting, commissioning or machine optimization, it can be helpful to have the highest possible degree of freedom in the evaluation of machine data. Microsoft Excel is a good and powerful tool for this. With the Excel Plug-in, data from the machine (process values, batch data, etc.) are written directly into the Excel worksheet and can be processed from there in evaluations as required.

Connecting Systems

Transfer-Objects

The respective Excel file can be dynamically determined or predefined. In case the Excel file does not exist, an error message can be optionally generated, or an new file can be created, named and saved.

Trigger

The Excel Plug-in does not have its own triggers and therefore works with the standard triggers of the OPC Router.

Browsing

The Excel Plug-in addresses rows in Excel files directly by referencing table sheets, columns and rows. The configured cells are shown a data fields in a visual display.