System integrator and OPC Router expert ZewaTec Automation

A system integrator designs a complete solution from various systems, technologies or software solutions. In doing so, he connects existing systems, adapts interfaces, monitors the integration, tests it and is also responsible for maintenance. The system integrator works closely with customers and partners to understand requirements and provide the best integration solution. In doing so, a system integrator draws on many different software solutions to create the optimal solution for the customer.

One such system integrator is ZewaTec Automation GmbH, based in Hamburg Moorfleet. Since 2011, ZewaTec Automation has been involved in the implementation of automation and digitization projects for customers at home and abroad. ZewaTec’s portfolio also includes the OPC Router. The connectivity diversity with the additional function of low-code programming makes the OPC Router something special for ZewaTec Automation: ZewaTec Automation itself has been successfully using the OPC Router in its projects for many years and has become an OPC Router expert during this time.

In our use case, the OPC Router is part of the solution strategy for ZewaTec Automation at their customer Hywax.

Hywax GmbH – leading specialist in wax technologies

Hywax GmbH is the leading specialist in innovative wax technologies, offering customers around the world a wide range of wax products of the highest quality and purity. It offers an extensive product portfolio that includes kerosene, microcrystalline and synthetic Fischer-Tropsch waxes, petrolatum, and customized blends and emulsions.

Hywax serves many different industries and business segments, including hot melt adhesives, polymer processing, printing inks, paints, coatings, rubber, tires, paper, packaging, textiles, cosmetics, pharmaceuticals, building panels, and road construction and candles, among many others.

The Hamburg-based company is part of the AWAX Group.

From a simple piece of paper to an Industry 4.0 solution

The initial situation: The piece of paper is replaced by several software solutions

A few years ago, Hywax still relied on manual data entry in its production using simple slips of paper: A production employee personally collected the printed order data from the ERP system from the responsible employee. The employee then had to enter the data on the machine’s user interface and start the production order manually. In addition to the high expenditure of time, there was always the risk of transmission errors.

In search of new ways to automate and digitize their business, Hywax came across the system integrator ZewaTec Automation. ZewaTec Automation had the task of replacing the paper slip and connecting the data from two Siemens systems and a Yokogawa control system with the ERP system SAP. The goal was to achieve an automated data transfer. To implement this task, ZewaTec Automation integrated many different partial solutions that together transferred the data from the SAP system to the machine. However, this solution entailed a lot of programming effort. Around 20,000 lines of code had to be written by the ZewaTec Automation experts to put Hywax’s requirements into practice.

The OPC Router – an Industrie 4.0 middleware that makes more possible

In the long run, the solution with many different software components was not optimal for Hywax and ZewaTec Automation. The interaction of the different partial solutions not only proved to be cost-intensive due to the many standard software licenses required. In addition, data transfer repeatedly stalled as soon as one software solution stopped working or was even switched off. In their search for an optimization of their digitization strategy, ZewaTec Automation turned to the OPC Router, which they had already been using in other projects for many years. It quickly became clear that OPC Router could meet ZewaTec Automation’s requirements while being able to replace the various existing heterogeneous software solutions and integrate them into one software platform. Together with the simplicity, flexibility and low-code programming, the use of the OPC Router was a done deal.

We implemented the setup of the OPC Router ourselves as far as possible. When we needed support, the OPC Router team was there immediately.

René Ries, CEO ZewaTec Automation GmbH

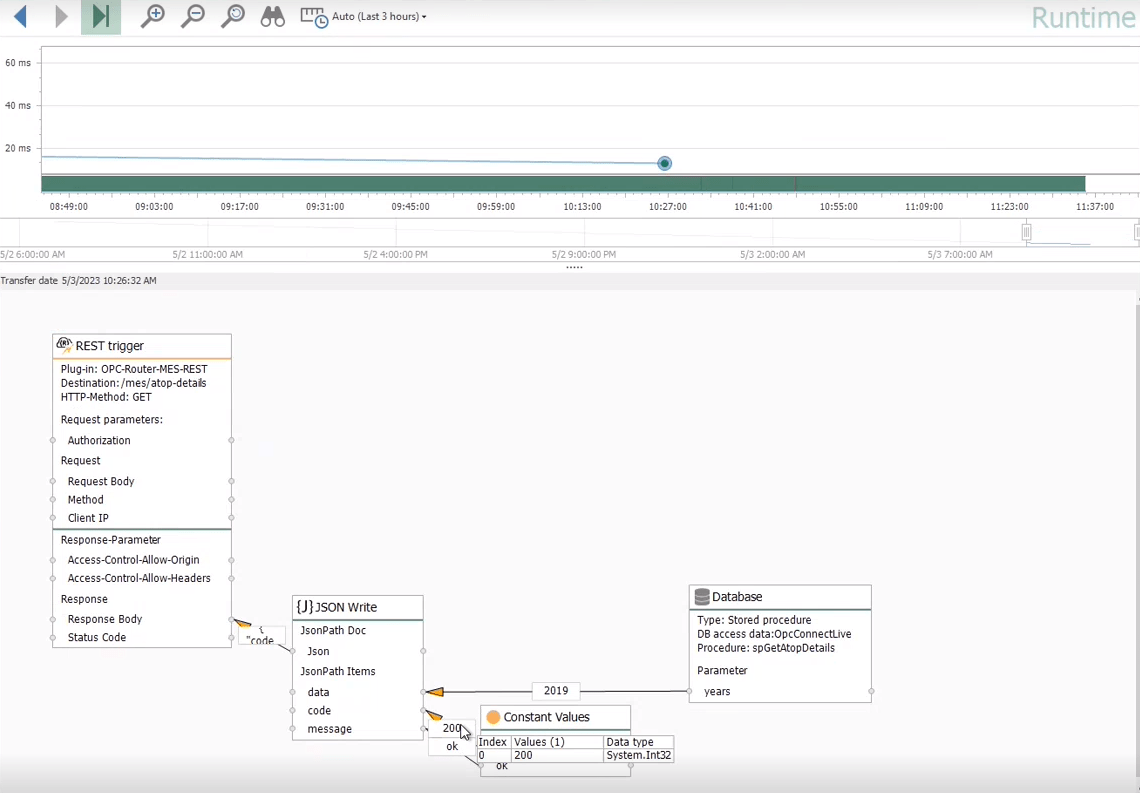

The OPC Router setup quickly led to success. On the user interface, the connections could be established via drag & drop and the systems coupled with each other. The data transfer from the SAP system to the Siemens and Yokogawa machines was thus quickly established and reliably guaranteed. The OPC Router was able to replace over 90% of the programming with its graphical connections. However, this was not the only task of the OPC Router. Thanks to its versatility, ZewaTec Automation was also able to develop an individual job control system for Hywax. Together with the OPC Router, this is tailored to Hywax’s needs and optimizes the processes. A production management platform could also be set up as a result, which has production-relevant data transferred from the OPC Router. This provides real-time production and efficiency control. The field of application of the OPC Router at Hywax covers a large portfolio and ranges from SAP systems, databases and e-mail distributors to various printers and scales at the field level.

The OPC Router acts as an open engine. It can flexibly implement what is needed.

René Ries, CEO ZewaTec Automation GmbH

The connectivity of the OPC Router enables ZewaTec Automation to build a digital system landscape at Hywax that also meets individual requirements. The additional individual and special requirements needed by ZewaTec Automation could be implemented with the help of the OPC Router. In case of questions or problems, the OPC Router experts were able to provide quick and competent support at any time.

The OPC Router as data supplier for visualization

ZewaTec Automation has already been very reliably used as a professional service provider for support at Hywax for more than 10 years. While the data transfer with the OPC Router runs smoothly in the background, ZewaTec Automation has also set up the company’s internal visualization with the OPC Router data. The visualization shows different data such as temperature or production status. The OPC Router serves as the data provider for this. Each query of the graphical user interface runs via the OPC Router, which acquires the data in the background and forwards it to the visualization.

The OPC Router as an Industrie 4.0 software solution

For the system integrator ZewaTec Automation, the OPC Router is a standard solution that convinces primarily through its simplicity and the many advantages for the end customer. Thanks to ZewaTec Automation, Hywax was first able to replace the paper accompanying slip and then, together with the OPC Router, automate internal processes and save costs and time compared to previous processes and software solutions. The OPC Router now provides important real-time information for the production process, runs efficiently in the background and thus successfully implements the Industry 4.0 project.

Hywax also relies on the OPC Router in the future

In the future, the OPC Router will continue to play an important role in the digitalization of Hywax. Through the OPC Router, ZewaTec Automation has received some new impetus during the course of the project at Hywax and has found ways to drive digitization even further. This gives the OPC Router as a software solution an even more important role than initially thought.

Since we have been using the OPC Router for our digitization, we have found some new options that we didn’t know existed.

Rudolf Mantke, Hywax GmbH

In the future, the OPC Router will allow us to implement even more options in visualization and data transfer in the background. Thus, the OPC Router remains an important part of any digitization strategy for ZewaTec Automation, not only at Hywax but also in many other projects.

More information

The OPC Router is a software that networks your machines and systems. It enables the connection of all existing systems and can modernize processes sustainably. Our video explains exactly how the OPC Router works, how it can be integrated into your system environment and what advantages it offers your company.

Read how the use of the OPC Router from inray at the bicycle manufacturer corratec creates fail-safety and avoids downtimes. The OPC Router creates more transparent data transfers from the ERP system to the control level.

See how the OPC Router leads to more transparency and efficiency in port logistics. In our case study, the innovative software solution leads to an optimization of the handling processes.