Bayer AG is a global company operating in 80 countries with core competencies in the life science fields of health care and agriculture. They develop products and services to tackle the world’s greatest challenges and meet the most important human needs for health and nutrition.

The Bayer Bitterfeld site was founded on October 25, 1991 and has been one of Bayer’s many and most digital sites ever since.

Challenges with a variety of individual solutions

Many different individual solutions

Before the OPC Router was used, the Bayer Bitterfeld plant already had a higher degree of digitalization than is usual. Many different individual solutions implemented what was needed. These individual solutions were either software from third-party providers or programs programmed by the managers themselves, which had to close the gaps in the other software solutions. Each department then had its own software solution that was responsible for delivering the relevant data.

Several meetings to create transparency

In order to compare this data with the other departments, it was first prepared individually by each department and then shared in various meetings. Several such meetings were necessary every day to create the necessary transparency and clarity and took about 2 hours a day. At the same time, these meetings caused a certain delay in the response. It took some time to collect all the important data from the different departments in order to be able to make a decision based on this data.

The OPC Router as a communication platform

Those responsible at Bayer Bitterfeld came across the OPC Router on the recommendation of another plant. The OPC Router was quickly integrated into the system and initially started its work on a test system. The most important connections were largely implemented by the responsible persons themselves. When difficulties came up, the OPC Router tutorials, which cover almost every application, helped. After the successful test phase, the OPC Router licenses for the required OPC Routers were purchased and used productively. Since then, several OPC Routers have been running smoothly at Bayer Bitterfeld and ensure continuous data communication.

The OPC Router is very easy to use. That was also our decisive argument for the purchase.

Matthias Schaller, Bayer Bitterfeld

The OPC Routers sit in the middle as a data hub and act as a platform that brings together all the data from the departments. They were able to completely replace any previous individual solution. The transparency created with the OPC Routers not only eliminates the need for daily meetings, but also creates potential for a suitable visualization of all data. Each department has been able to create its own visualization, where they can see at a glance which data is relevant to them.

We always have all the data visible to everyone in the company at all times.

Matthias Schaller, Bayer Bitterfeld

IT / OT – Coupling with the OPC Router

The OPC Router provides all important information for visualization directly on the machine. This includes production statuses, open orders and the current status of the machine. This makes it easy to see whether a machine is running properly, which orders are still open and what the status of current production orders is.

To do this, the OPC Routers collect the machine data via OPC UA from an OPC Server, in this case the KEPServerEX from Kepware. The data is also sent to a MongoDB so that it can be retrieved in the long term. An e-mail notification is also set up to inform affected employees about a production outage or deviating data.

The many different OPC Router interfaces make it an indispensable data supplier for our production.

Matthias Schaller, Bayer Bitterfeld

OPC Router plug-ins make even more possible

Since using the OPC Router, the number of applications with the OPC Router has steadily increased. It quickly became clear that the OPC Router could be used to implement even more connections, collect more data and display it for other departments than was previously possible. The OPC Router has revealed how much useful data from Bayer Bitterfeld can still be evaluated and analyzed, collected and transferred to other departments.

New applications are constantly being created to digitize other processes and continuously increase the degree of digitization. The OPC Routers used will therefore continue to provide new possibilities for data transfer and transparency at Bayer Bitterfeld in the future.

Further information

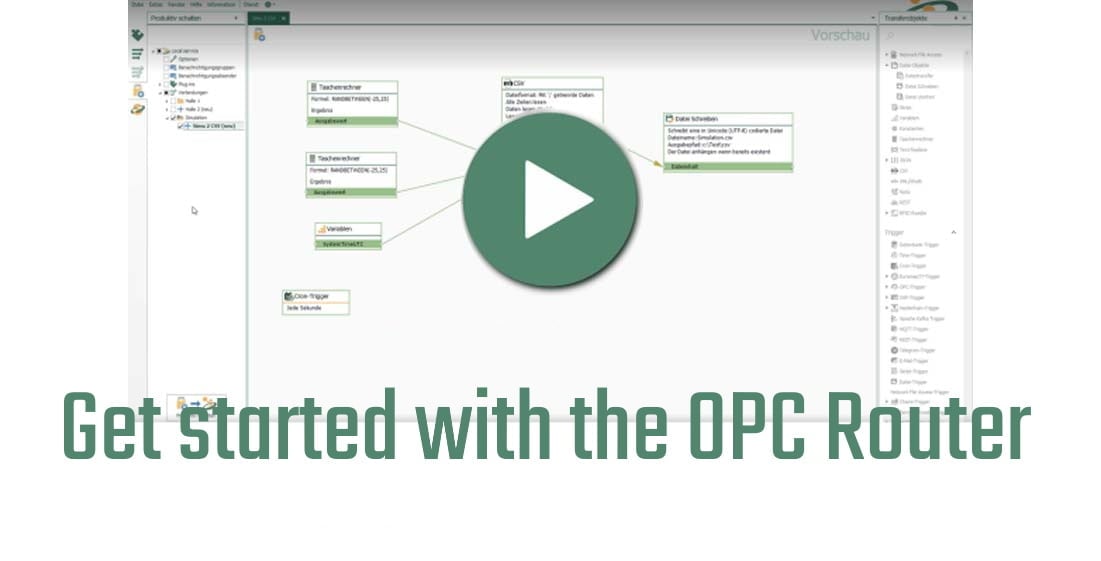

The OPC Router is software that networks your machines and systems with each other. It enables the connection of all existing systems and can modernize processes sustainably. Our video explains exactly how the OPC Router works, how it can be integrated into your system environment and what benefits it offers your company.

Read how the use of the OPC Router from inray at the bicycle manufacturer corratec creates fail-safety and avoids downtimes. The OPC Router creates more transparent data transfers from the ERP system to the control level.

See how the OPC Router leads to greater transparency and efficiency in port logistics. The innovative software solution leads to an optimization of handling processes in our case study.