RFID-AutoID (OPC UA)

RFID via AutoID Standard

Working with RFID readers has long been characterized by manufacturer-specific protocols and connection types. With the OPC UA AutoID Companion Specification, this has now fundamentally changed. In the specification, communication with the reader is standardized and the communication protocol is set to OPC UA. Thus, manufacturer independence is achieved on the application side.

The OPC Router implements the RFID part of the AutoID specification and is therefore able to easily connect compatible RFID readers and integrate them into Industry 4.0 environments. AutoID compatible readers are available e.g. from Harting, Siemens and TURCK.

That’s how easy it is.

RFID-AutoID connection via drag & drop

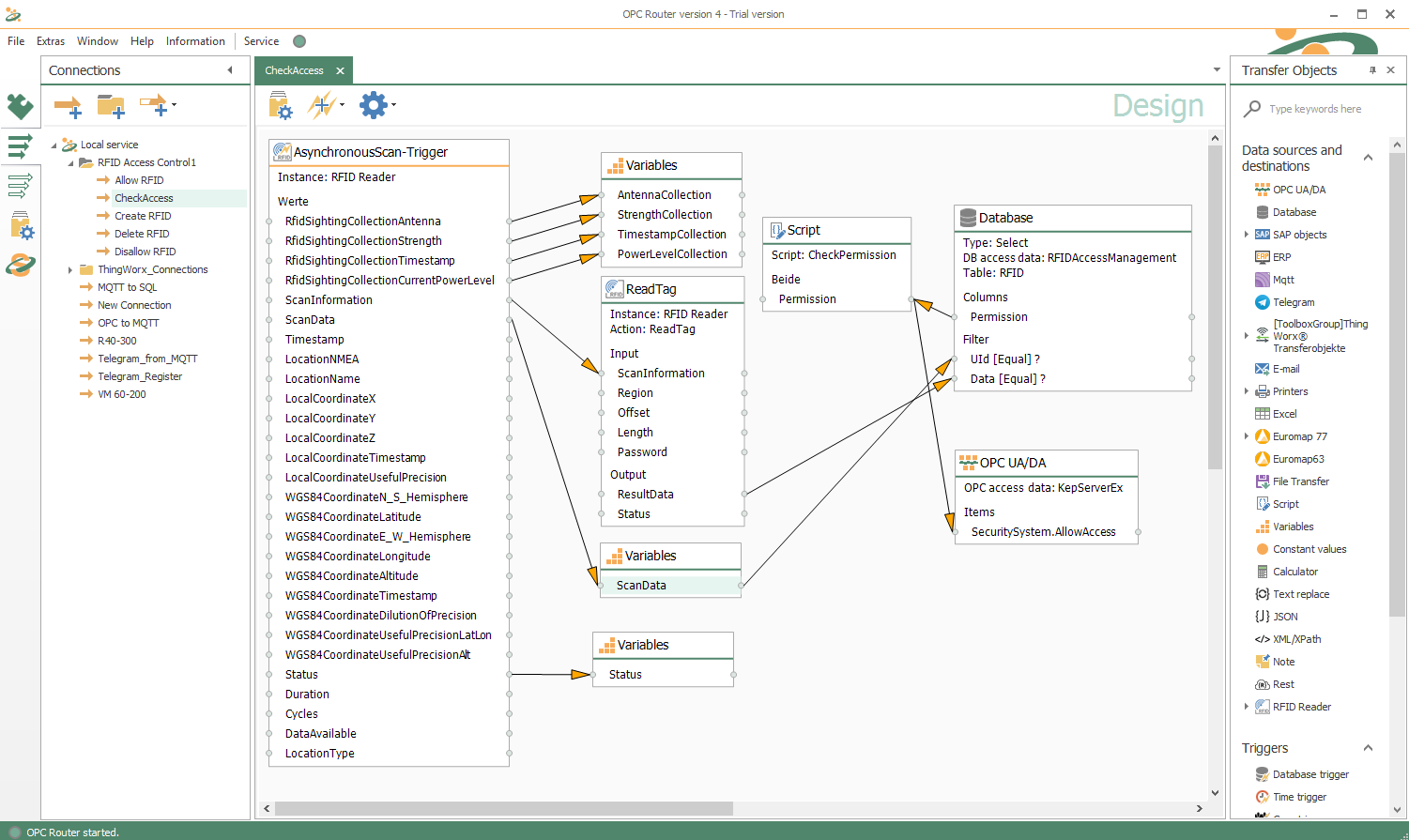

Connecting your systems to an RFID reader is very easy and intuitive with the OPC Router via drag & drop. This screenshot shows you an example of an application of the OPC Router and an RFID reader. First, RFID tag data will be read as soon as a tag is in the reading field. Then the access query is made from a database with forwarding of the access right to a PLC via OPC UA.

Bringing Industry 4.0 to life with RFID-AutoID

- Achieving more with coupled systems:

By the simple integration of RFID readers with the new standard, different systems can be fed with RFID data in a simple way and processes can be controlled more efficiently. - Industry 4.0 with RFID AutoID:

For Industry 4.0 it is essential to provide the right information about workpieces and raw materials to the right systems at all times. The simple integration of RFID-AutoID systems makes it possible to supply any system at any time with important identification data, which can then be used to determine the associated production data. RFID data is no longer reserved for special isolated solutions. - About OPC Router:

The OPC Router offers a visual network configuration interface for successful cross-linking of your systems. A high variety of Plug-ins turn the OPC Router into a powerful data hub for industrial applications.Easy configuration, sophisticated monitoring and robustness are main distinguishing features of the OPC Router.

RFID-AutoID Plug-in application examples

RFID identification transferred to PLC

RFID readers supporting the Auto ID Companion Specification provide the read RFID code in a standardized way. With the appropriate OPC Router Plug-in, this code can be passed on to any system. For direct process control based on the identification, the code can be transferred directly to the controller (PLC) with the OPC UA Client Plug-in, which then starts special processes or adjusts parameters accordingly.

By controlling the process through the identification of the product itself, one of the central Iindustry 4.0 visions is implemented: self-controlled production.

Easy setup of Track & Trace databases

Traceability thrives on data records that prove when which product was handled and processed where and how. The data records are stored in a central database for comprehensive evaluation. With Auto-ID-enabled RFID readers and the OPC Router Plug-in for Auto-ID RFID readers, new identification points can be added very easily. RFID codes provided by Auto-ID are then transferred to the corresponding Track & Trace database using the OPC Router and the SQL Server Plug-in. In this way, traceability is constantly being refined without the need for software development for the connection.

Connecting Systems with the OPC Router OPC UA Client Plug-in

Transfer-Objects

The transfer object of the OPC UA Client plug-in allows access to the data points of the OPC Server.

Data Points

The OPC standard defines the structure and organization of data points. Each data point has a unique name. As an OPC client, the OPC server provides the current value, the associated time and the quality of the value (device connected, no connection, etc.).

The desired data points are selected via browsing. These are available in the transfer object of the graphical configuration and can be connected to other fields during the transfer

Trigger

The OPC UA Client Plug-in includes several triggers.

DataChange Trigger

The datachange trigger is configured for an OPC data point and triggers the transfer when the data point changes.

Limit Trigger

The limit value Trigger monitors a data point for compliance with limits. It can be checked for exceeding or falling short. A hysteresis can also be set.

Bit trigger

Handshakes are often implemented for data transfers. The bit trigger is the simplest variant here. The OPC router checks whether a bit requests a transfer. Once transferred, the bit is optionally reset or another bit is set as response. The success of the transfer can be transferred to another data point.

Message Trigger

The message trigger is the further development of the bit trigger in the form of telegram data exchange. Here not a bit is checked, but a counter is checked for a value change. In response, the number that triggered the transfer is written back after the transfer.

The reliability and traceability of this exchange is significantly higher.

Browsing

The OPC UA Client Plug-in can browse the data points of the OPC server.

Data Point Hierarchy

The OPC Standrad defines the possible ways to read data points. The standard is the hierarchical structure in form of a data point tree. The OPC Router reads all data points as a tree and displays them to the user. In this form, even large datapoints are easily accessible. Each data point is identified via the unique path and is taken over including type information.