Successful Cooperation: inray OPC Router in Use at AURIA

At the plant in Straubig, AURIA Solutions GmbH (Germany) manufactures car flooring systems for just-in-time or just-in-sequence delivery to various premium-segment car manufacturing plants. Short-dated distribution sequences need to be attained – while offering a wide range of product variants, complying with high quality requirements, and ensuring complete traceability. To accomplish this, AURIA enhanced its SAP-based ERP system with a comprehensive automated production control system offered by inray Industriesoftware GmbH (Germany). Thus, human and manufacturing resources seamlessly work together to achieve best-in-class performance.

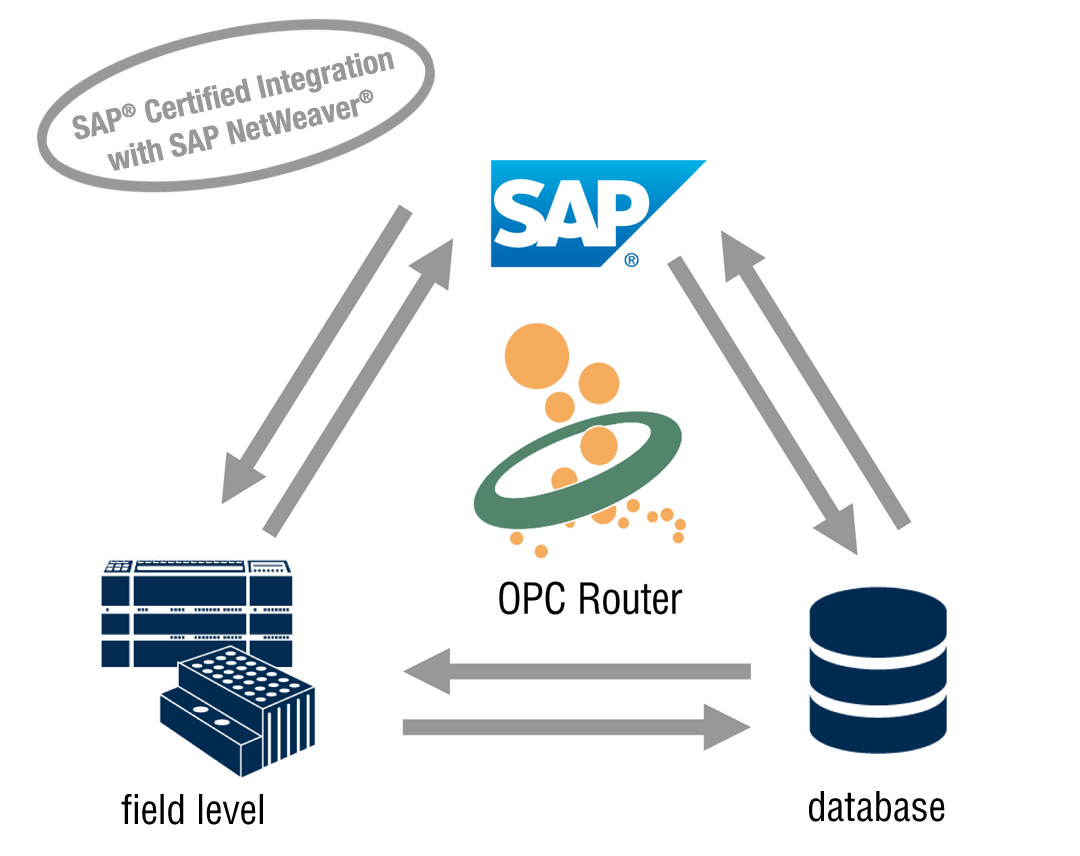

OPC Router for coupling of SAP and PLC / OPC

AURIA and inray look back on twelve years of thriving technological partnership with each other, during which inray developed a highly lean – redundantly protected – automation solution according to customer-specifications. Today, the customized solution controls and documents all production processes in direct communication with PLC, label printers and SAP. This multifaceted connection is only made possible by SAP’s standardized interfaces. At the lowest level, all SPS controls for each single station, such as the hydraulic deep-drawing presses, transport systems or water jet cutting systems, are connected with one KEPServerEX by Kepware. At the chief control level, the SAP-based ERP system provides information on raw material and formulas used, as well as on deep drawing tools and production programs. It also informs about how the planned products and the processes for storage and release are going to be triggered, and determines the perfect delivery times and sequences. Moreover, the OPC Router controls communication flows by providing a programmable data hub, which comes with a visual interface. This is where the SPS signals are configured that are sent to SAP, or to other peripheral devices. And from here SAP data flows to PLC and to label printers, which are located in various places.

IT administrator Michael Kalbe states, “The visual interface allows easy OPC configuration without extended programming knowledge. Commonplace alterations can be carried out independently, without further assistance.” If necessary, small program routines can be easily implemented; or templates for various processes can be copied or adjusted. Data transfer occurs via Remote Function Call (RFC) with handshake functionality, which substantially improves overall system reliability and security. Status updates occur every 10 seconds.

To reduce network data volume, only compressed data is sent, which decompresses once it arrives at its designated location.

“The OPC Router displays current transfer processes as visual renderings,” states M. Kalbe. “Thereby making it easy and fast to locate errors and to solve them; for instance if the SPS does not send data anymore or one of the label printers doesn’t work anymore.”

Michael Kalbe and Christian Gaßmann from Auria Solutions GmbH

More information

OPC Router works as an universal translator for your systems. It enables the communication

of all existing systems and protocols and can help modernize processes in the long term. Our video explains how OPC Router works, how it can be integrated into your system environment and what advantages it offers your company.

OPC Router is multifunctional and very easy to use. Connections are created simply by drag & drop and numerous Plug-ins enable the connection of a wide variety of applications and systems. Read more details about the advantages of OPC Router and how you can achieve an automated data exchange and thus the optimization of your processes.

Getting started with OPC Router is easy and can be done quickly. Our video shows you which elements are important and how you can connect different automation systems via drag & drop with suitable Plug-ins.

Run a free test now!

Get your personal link to the most recent OPC Router version and sign up for product news.